How to Use the ReLoad System

A clear, step-by-step guide to loading, using, cleaning and reloading the ReLoad System, so your guns stay running and your bond lines stay clean.

How It Works

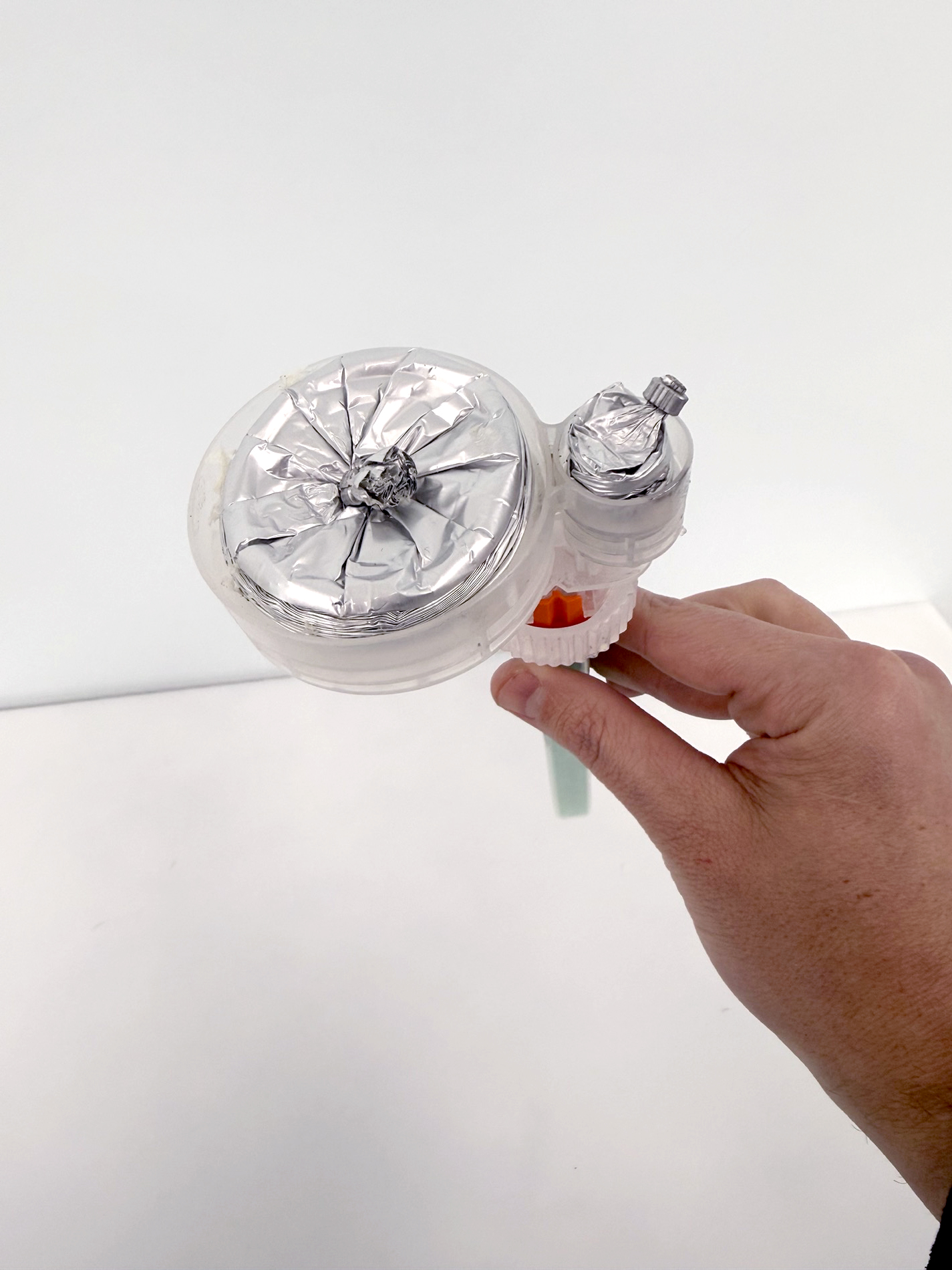

Step 1: Load the Foils

Load the adhesive foils into the reusable cartridge body. Be mindful to load resin and activator in correct slots.

Step 2: Attach the ReLoad Cap

Once both foils are inserted, snap on the top piece of the ReLoad system until it clicks securely.

Step 3: Ensure Adhesive Pods Get Punctured

Before the tip is on, cartridge should be inserted into the gun and both resin/activator should dispense before tip is added. Just mention to make sure both resin and activator side are flowing out. If they aren't, use the nose piercer for a double pierce.

Step 4: Secure the Tip

After foils are inserted, snap on the top piece of the cartridge until it clicks securely. 4-6 inches should be bled from tip to ensure both resin/activator are being used

Step 5: Dispense

Using your manual or pneumatic glue gun, pull the trigger and start dispensing as you would with a traditional cartridge.

Step 6: ReLoad

Once the product is all dispensed, snap off the cap and dispose of the foil shells. If using the same adhesive formula, flip and reload with new adhesive pods, periodically cleaning when required.

Why Use ReLoad?

- End single-use cartridges

- Fast changeovers

- Compatible with most standard 1:1 and 10:1 guns

Quick, Simple Cleaning

Most day-to-day cleanup on the ReLoad System can be handled with a couple of simple habits:

When to Reuse

Reuse the cartridge any time you still have adhesive left inside. Leave the top snapped on and the used tip attached, remove the cartridge from the gun, and store it at room temperature. When you’re ready to use it again, remove the old tip, confirm both resin and activator are dispensing freely and aren’t clogged, then attach a new tip and resume dispensing.

When to ReLoad

ReLoad the cartridge when all adhesive has been used. Remove the cartridge from the gun, snap off the clear top, and use your fingers or pliers to pull out the used foil pods. Flip the green shell, insert the correct resin and activator pods, remove the old tip, then snap the clear top back on. Place the cartridge into the gun, make sure the pods are punctured, and purge material before attaching a new tip and starting to dispense.

When Solvents Make Sense

Most of the time, you won’t need solvent at all, especially if you’re running the same product and the resin and activator sides haven’t been cross-contaminated. In those cases, a little dried material at the nose is normal and can simply be let cure and scraped away. If things get genuinely messy or you know contamination has occurred, you can use a suitable solvent to wipe the affected area with a disposable rag.

Some shops may choose to soak components in a solvent bucket, but we recommend treating that as an occasional cleanup method rather than an everyday practice.